Non Destructive Testing and Inspection Services

PRESSURE VESSEL INSPECTIONS

RITC (Pty) Ltd provides inspection and testing services to ensure that pressure vessels are fit for service and legally compliant to the Pressure Equipment Regulations. All inspections and tests are carried out by suitably qualified and competent SAQCC/ SAIW certified inspection personnel.

In cases where vessels are not compliant with the Pressure Equipment Regulations, recommendations are provided to attain legal compliance and remain in service.

Types of inspection services offered:

Third party inspection and design verification on newly manufactured pressure vessels.

- Pre shipment inspection including conformity assessments.

- Pre commissioning inspection of newly installed pressure vessels.

- Statutory inspection of in-service pressure vessels.

- Re instatement to conformity of non-compliant pressure vessels.

- Third party inspection on repairs to pressure vessels.

- API 510 pressure vessel inspections.

Codes, standards, specifications and the Health and Safety regulations to which RITC are accredited to are referenced on our SANAS schedule of accreditation.

STEAM GENERATOR (BOILER) INSPECTIONS

RITC (Pty) Ltd provides inspection and testing services to ensure that steam generators are fit for service and are legally compliant and in accordance with the Pressure Equipment Regulations. All inspections and tests are carried out by suitably qualified and competent SAQCC/ SAIW certified personnel. In cases where steam generators are not compliant with the Pressure Equipment Regulations, recommendations are provided to attain legal compliance for continued operation.

Types of inspection services offered:

Pre- commissioning inspection on newly installed steam generators.

- Third party inspection and design verification on the manufacturing of steam generators.

- Third party inspection on repairs of steam generators.

- Re instatement of conformity of non-compliant steam generators.

- In- service inspection of steam generators:

- 3 yearly – Fire Tube steam generators

- 3 yearly – water tube and electrode boilers

- 12 monthly – Fire Tube Steam generators

THIRD PARTY AIA INSPECTION

Types of inspection services offered:

- New fabrication of pressure equipment (Typical codes of manufacture ASME VIII, PD 5500, ASME B31.1, B31.3, B31.4, B31.5, B31.8 & API 650)

- Fabrication of Structural steel structures (AWS D1.1)

- Fabrication of Bulk Vertical Storage tanks (API 650 & 653)

- Fabrication of Pipelines (ASME BS 31.1,3,4 & 8, API 1104)

- Repairs and Alterations to above (API 510, API 570, API 653, NBIC & ASME PCC-2)

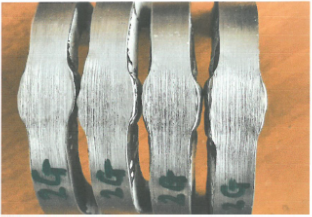

WELD PROCEDURE QUALIFICATIONS AND WELDING QUALIFICATIONS:

Through our qualified and experienced welding inspectors we can assist in the preparation and qualification of manufacturing weld procedures to various national and international codes and specifications.

Weld procedure qualifications:

- Witness welding of test piece.

- Mechanical testing and radiographic testing of the test piece as per code requirements.

- Drafting and approving weld procedure qualifications according to various codes such as ASME VIII, AWS D1.1, EN 14025 and 9606

- Drafting of qualified and prequalified procedures.

Welder qualifications:

- Witness welding of test piece

- Mechanical testing and/or radiography of test piece as per code requirements.

Drafting of welder qualification certificates according to codes such as ASME VIII, AWS D1.1, EN 14025 and 9606

API 653 STORAGE TANK INSPECTIONS

In service and out of service inspections are carried out in accordance with API 653 recommendations. Visual inspections are carried out by our API inspectors who are qualified and certified to API 653 requirements. These inspections are supplemented by specialized high-tech testing techniques to enable our clients to be provided with a detailed integrity and condition report including estimated remaining life and retirement dates for the tank.

API 570 PIPING INSPECTION AND CERTIFICATION

- Our API 570 Inspectors have inspected and certified pipelines ranging from large diameter lines used in oil and gas production through to smaller diameter pipelines used in Petrochemical plants, refineries and depots.

- The inspection code covers in-service inspection, rating repair, and alteration of metallic and fiberglass-reinforced plastic (FRP) piping systems and their respective pressure relieving devices.

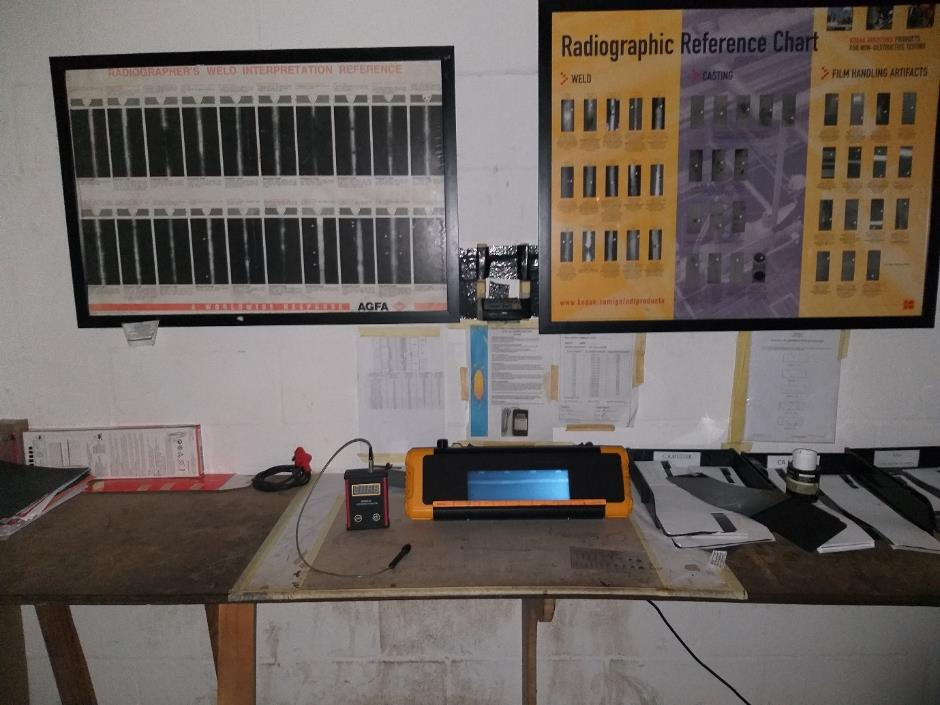

NON-DESTRUCTIVE TESTING

Non-destructive Examination (NDE) is defined as those inspection methods, which allow materials to be examined without changing or destroying their usefulness. NDE methods are employed to ensure that a WELD meets design specifications and does not contain defects. An NDE method is chosen that has the capability and adequate sensitivity to detect discontinuities in the WELD JOINTS requiring examination for accept/reject evaluation. Discontinuities in welds that are detectable when using NDE methods are Porosity, Incomplete fusion, Incomplete joint penetration, Undercut, Underfill, Lamination, Cracks, Root Concavity, Slag Inclusion Etc.

Below are the NDE methods that RITC (Pty) Ltd offer:

Ultrasonic Testing:

Surface Flaw Detection:

Radiographic Testing: (RT)

Advanced NDT:

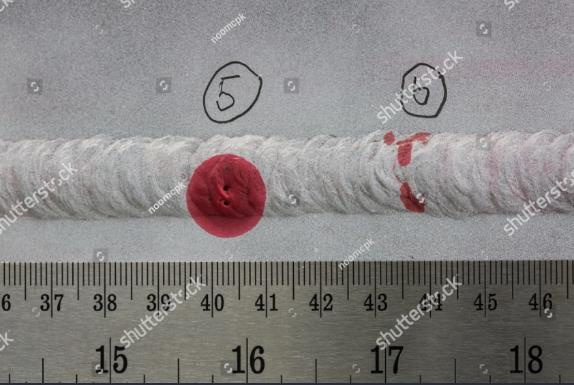

NDT VIA ROPE ACCESS

Rope access is an advanced access method that is used as an effective alternative to conventional scaffolding or cradle systems. Personnel are highly skilled in rope access techniques and related activities with accreditation conforming to the relevant codes of practice. The teams involved on a job are normally IRATA certified Level 1, Level 2 and Level 3 technicians.

NDT and Inspection methods that can be carried out using Rope Access are the following:

- Magnetic Particle Examination. (MT)

- Liquid Penetrant Examination (PT)

- Ultrasonic Examination. (UT)

- Thickness Measurements. (UTM)

- Radiographic Examination. (RT)

- Positive Material Identification testing. (PMI)

- Visual Inspection. (VT)